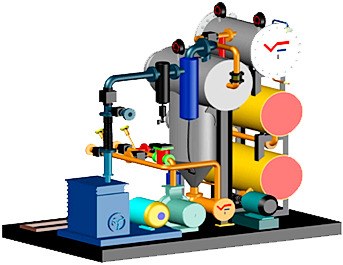

Macrotech Filterall : Transformer Oil Filtration Machines

having fully equipped ISO 9001:2008 certified modern factory at Jamnagar, Gujarat (INDIA) &

branch office at Kolkata, West Bengal (INDIA).

equipped with engineers having rich knowledge on manufacturing of transformer oil filtration machines over 2 decades & is being lead forward by young turks.

over 1400 Macrotech make transformer oil filtration machine are running across 5 continents successfully.

Macrotech make plants are proven to be most popular, high performing & aesthetically

beautiful amongest all.